Our Subteams

During our season, Eagle Evolution divides itself into five groups called subteams. Each subteam focuses on developing a specific aspect of the robot. Similar to the various engineering fields, our subteams reflect different disciplines within the engineering world. We have electrical, fabrication, design, business, and programming subteams that each work collaboratively during the season to produce a finished robot and presentable team. Before our season begins, mentors and students leaders run modules, which are classroom-like sessions for each subteam to train and educate members about the engineering process, and the challenges they will have to solve during the season.

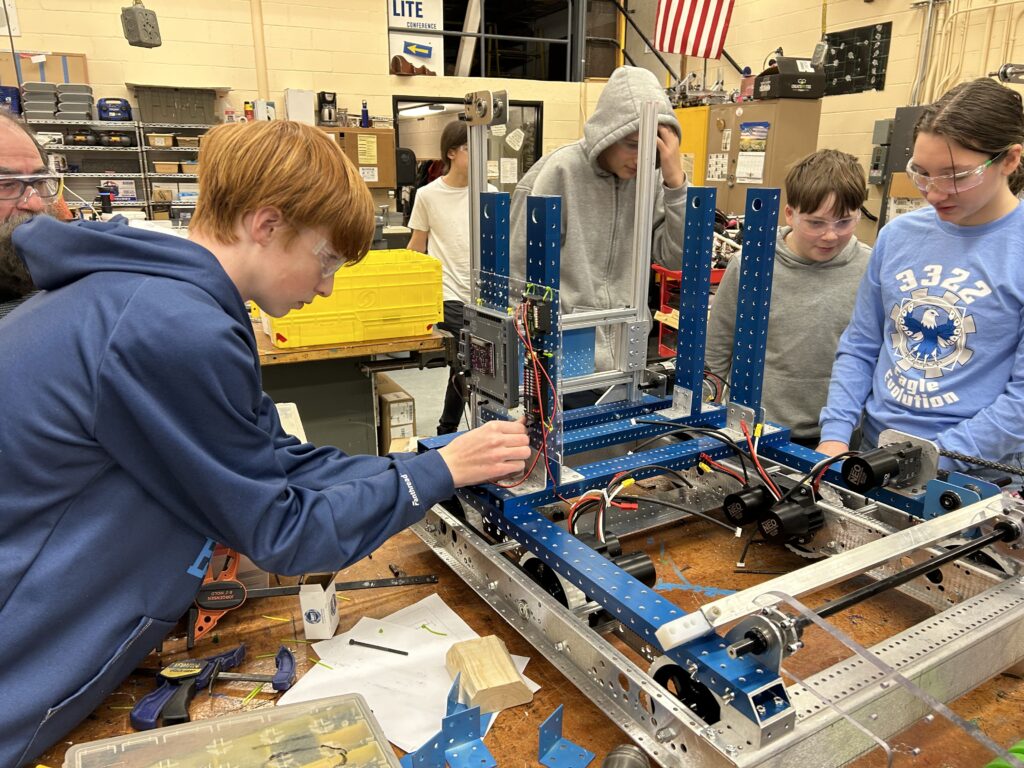

Fabrication

The fabrication subteam works with the heavy machines in our shop to create the parts we need to assemble our robot and our playing field. They receive graphics from the design subteam that they turn into robot and field parts and train to use our shop tools during our preseason. In addition, they often work with the design team to assemble parts of the robot. This action requires good communication between the two subteams. Our team is fortunate to possess a fabrication tool called a CNC (Computer Numerical Control) Machine. This makes it possible for us to fabricate unique parts that we would otherwise be unable to produce by hand in a timely way. There are only a few students trained to operate the machine.

Design

The design subteam is responsible for the conceptualization and prototyping of the mechanical aspects of our robot. They brainstorm, test, and CAD our robot. Because there are so many components to cover, this subteam often splits into groups that each have one mechanism that they focus on; For example, a group might be working on the shooting mechanism while another is working on an intake system. These divisions make it more important for the two students running the design subteam to closely manage projects, communicate with the team captains, and update other subteams on their progress.

Electrical

This subteam focuses on – you guessed it – the electrical components of the robot. Most mechanisms on our bot require power to function, so our electrical boards and CAN (Computer Aided Network) systems must be in pristine condition. The electrical subteam does much of its work in the latter part of the season once we have a chassis built and ready to test. Until then, they help the design team wire up prototypes and plan wire routing.

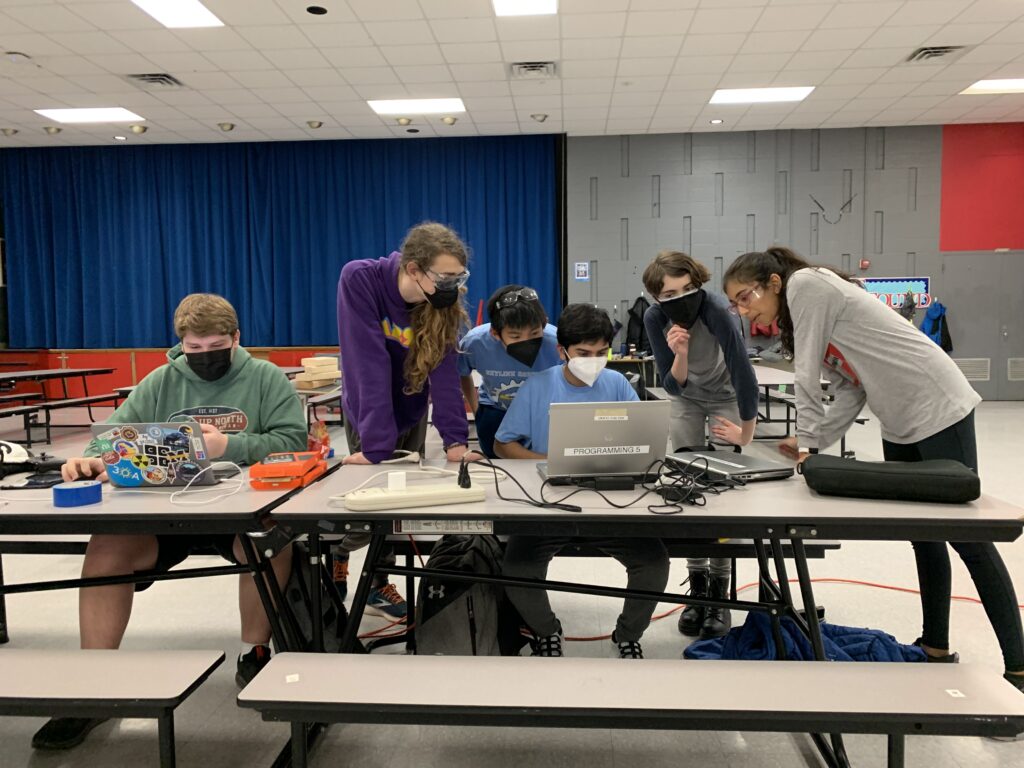

Programming

Our programming subteam is responsible for getting the robot to respond to certain inputs that come in from the drivers through two x-box controllers. In addition, they develop an “autonomous program” for the beginning of games that allows the robot to preform pre-programmed tasks without the assistance of drivers, scoring points for the team. Other projects they work on during the season include developing LED lights to go on the robot, and aiding in the testing of prototypes.

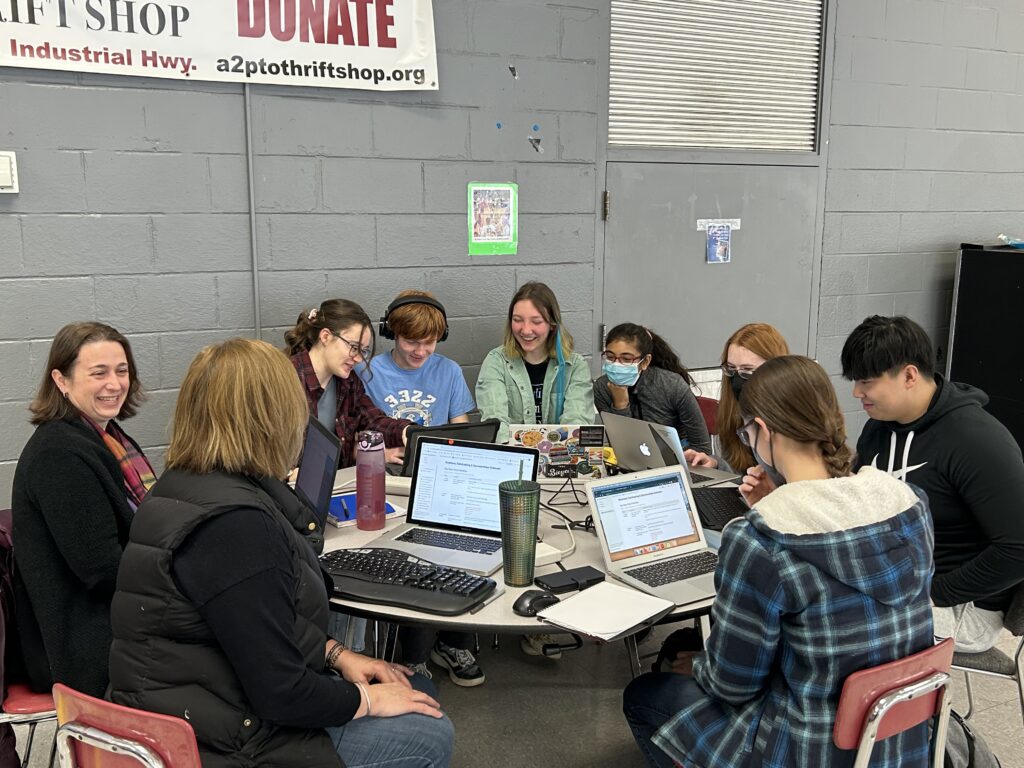

Business

3322’s Business team handles aspects of our team operation that are not robot related. They are responsible for many things such as website development, implementing our branding strategies, social media management, reaching out to other FRC teams, and organizing outreach events. Upholding our teams mission and keeping up with sponsorship status among other team finances are some other things that the Business Subteam is responsible for. On of the biggest Business projects of the year is completing the “Impact Award” submission which is a presentation, essay, and video compiling the ways that our team impacts our community, school and team positively to spread FIRST robotics mission